low speed impact drop tests|impact force drop testing : solutions Instron has more than 80 years experience in designing impact testing systems to simulate real-life impact conditions. Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The latest tweets from @Belotospfc

{plog:ftitle_list}

WEBBaixar Por Lugares Incríveis torrent. Assistir Por Lugares Incríveis (2020) Dublado Full HD. baixar filmes. faça download Por Lugares Incríveis 1080p online. Download Por .

In this investigation a test approach was developed to characterize the low-speed impact performance of foam-supported fibrous composite laminates in personnel protection applications.

The most commonly preferred frame rate for high-speed cameras used in experimental studies conducted so far are normally in the range of 1500–5000 fps for drop-weight impact tests on concrete, hot-rolled steel, and . For low-velocity impact testing, drop weight, Charpy, and Izod tests are available. Medium-impact velocities can be achieved with the aid of an inertia wheel or servo-hydraulic systems. For high-velocity impact tests, gas .

Reasons for Impact Testing. Impact testing is performed to determine the energy absorbed or the energy required to fracture a unit under test (UUT). Take for example a straight-line collision, .

Instron has more than 80 years experience in designing impact testing systems to simulate real-life impact conditions. Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models.A dropped-weight test apparatus has been developed that can be used to perform low-speed impact tests on composite aircraft structures. This vertical drop-weight test apparatus is . In this study, RCAR [20] (40% offset impact) and IIHS [21] (100% rigid wall and column impact) in low-speed frontal crash regulations are considered to assess the .

Models containing different indenters and plate shapes are also built to systematically study their influence on the low-speed drop-weight behaviour of composite . Low-velocity impact tests on the LSFC composite slabs were conducted by employing an ultra-high heavy-duty drop hammer testing machine. The tests revealed the failure mode, impact force and displacement response . Drop weight impact testing machines can perform a variety of impact tests, including puncture resistance, CAI test (Compression After Impact), tensile impact, 3-point bending, and wedge peel. Each test involves .

Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before . The quasi-static compression test was performed at speed of 500 mm/min. The tests was also executed using an Instron 3382 machine at room temperature 23 °C. The universal test machine was equipped with a high-speed data acquisition system of load–displacement and stress–strain. Roma Plastilina No. 1 clay has been widely used as a conservative boundary condition in bulletproof vests, namely to play the role of a human body. Interestingly, the effect of this boundary condition on the ballistic performance of the vests is indiscernible. Moreover, back face deformation should be characterized by measuring the indentation in the deformed clay, . To test the accuracy of high-speed stress microscopy (Fig. 2b), we used the commercial finite-element software ABAQUS to simulate solid-sphere impact, which has a shorter time scale than drop .

After impact, P has a rebound speed of v P3 eventually reaches a maximum height of h 4 . The above result says that we can extract the COR for an impact during a drop test by taking the square root of the ratio of the rebound height to the initial drop height. . Low values of COR show rapid reduction of the rebound heights. Questions: Based .RCAR Low-speed structural crash test protocol 8 / 18 Issue 2.3 5.0 TEST FACILITY AND TEST VEHICLE PREPARATION - REAR IMPACT The test facility and preparation of the test vehicle shall be similar to that described for the front impact (section 4.1 and 4.3), with the following additions/exceptions: 5.1 Barrier set up and position

work energy impact test

A dropped-weight test apparatus has been developed that can be used to perform low-speed impact tests on composite aircraft structures. This vertical drop-weight test apparatus is simple, compact, inexpensive and has precision impact and self-arresting design features similar to the more sophisticated, expensive test machines. The test apparatus has . The low-speed impact test is performed with drop-weight impact equipment, and the findings are reported in this article. The resistance to impact and failure of the aluminum sheets are investigated. Different heights of the impactor and the varying thickness levels of the specimen determine the performance of the impact test apparatus.damage to the structure of passenger cars in low speed crashes, a 15 km/h, 40 % overlap test was implemented in the 1980s and revised again in 2006 (the impact angle was changed from 0° to 10° and the rear impact moving barrier weight was increased from 1000 to 1400kg). This test is referred to as the RCAR Structural Test. We compare numerical analysis using the current model with existing experimental observations to validate the model. Next, the model is used to study the effect of stacking sequence, impact energy, indenter shape and plate shape on the response of composites under low-speed drop-weight impact. 2. Composite damage model for impact2.1.

Film Pendulum Impact Tester distribute

For all bumper tests, the impact barrier is 1,524 mm wide with a 3,404 mm radius and a flat 102 mm vertical surface (Figures 1, 3, 4, and 6). The barrier is constructed of 12.5 mm steel plate . Thus the impact speed recorded is the average speed over the 456 mm length of vehicle travel, which ends approximately 150 mm before the vehicle’s .ZwickRoell has been delivering high-quality impact test equipment for years. Based on this experience, ZwickRoell has developed a new drop weight tester product series under the name Amsler.. Plastics become brittle under load at high speeds and low temperatures.Therefore, the temperature response of plastics and their strength dependence on loading rate are investigated.

The US Army Operational Test Command’s Airborne and Special Operations Test Directorate (ABNSOTD) has carried out low-velocity airdrops of infantry squad vehicles (ISVs). The ISV is designed to enable the Army’s Infantry Brigade Combat Team (IBCT) personnel to cover tough terrains in a short span of time.

Automatic Surface Tension Meter distribute

what is impact testing

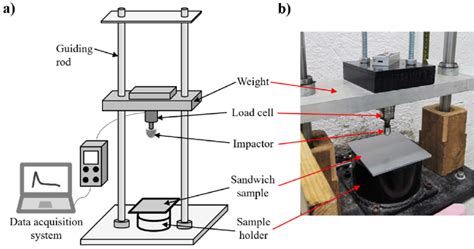

Experimental Procedure. An in-house built low-velocity drop-weight impact testing equipment, shown in Fig. 3a, was utilized as per ASTM Standard D7136 [].The plates were supported by four toggle clamps, as shown in Fig. 3.A steel impactor or a tup with a 0.025 m diameter hemispherical striker tip attached to a 22 kg deadweight was dropped from a fixed . Drop weight impact test standards. ASTM E208, ASTM D7136, ASTM D3763, ASTM F1459. . Video analysis software processes high-speed camera footage to analyze the impact event frame by frame. This software can measure displacement, velocity, and strain from the video data, providing a detailed visual understanding of the material's behavior. .Increase your characterization data with the use of high-speed cameras. The 9400 Drop Towers are equipped with a high-speed camera connection to allow . 2 Load in dynamic conditions depends on the test type and impact forces 9400 SERIES SPECIFICATIONS. 15 9450 Energy range J ft-lb 0,59 - 757 0,44 - 558 . Instron 9400 Series Impact Drop .

developed that can be used to perform low-speed impact tests on composite aircraft structures. This vertical drop- weight test apparatus is simple, compact, inexpensive and . The basic idea in a dropped-weight test is simply to drop an impactor or a weight of a given material and size onto a specimen from a given height to generate low-speed im-

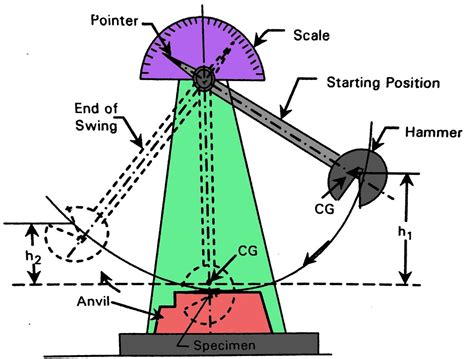

Data were collected over a series of 12 tests with bullet-to-target-vehicle contact angles ranging from approximately 45° to 315° with corresponding impact speeds of approximately 12.5 km/h (7.8 mph) to 16.1 km/h (10.0 mph). . Swinford, S., Furbish, C., Jones, B. et al., "Methods for Quantifying the Impact Severity of Low-Speed Side Impacts .Brittle materials have low toughness as a result of the small amount of plastic deformation that they can endure. The impact value of a material can also change with temperature. Generally, at lower temperatures, the impact energy of a material is decreased. . There are basically two types of impact tests: pendulum and drop weight. Izod . To investigate the low-speed impact response of the BR1200HS steel and AA6082 aluminum alloy self-piercing riveted (SPR) joint, low-speed impact tests with impact energies of 2.5 J, 5.0 J, 7.5 J, 10.0 J, 12.5 J, 15.0 J, 20.0 J, and 30.0 J were conducted utilizing a drop hammer impact tester. The results show that with the increased impact energy, the .

One of the problems with composites is their weak impact damage resistance and post-impact mechanical properties. Composites are prone to delamination damage when impacted by low-speed projectiles because of the weak through-thickness strength. To combat the problem of delamination damage, composite parts are often over-designed with extra .

Impact testers and Charpy impact testers Pendulum impact testers Drop weight testers Plastics and metals applications More information. Jump to the content of the page . For impact tests on metals, ASTM E23 permits a speed that can also be maintained with the HIT50P. This requires special accessories. Type of test: Product/ method standard: Low speed impact of pristine and aged solid high explosive,” in Proceedings of the Twelfth (International) Symposium on Detonation, Office of Naval Research, San Diego, CA, 2002. 20. . Numerical analysis on the ignition mechanism of explosive in drop weight test,”

served in low-speed laboratory impact experiments [6]. There, steel balls of various diameters D b were dropped into sand from various heights H; the resulting crater diameters scaled as D c D3 b H 1=4. For high-speed impacts in loose sand, however, ballistics data support D c 1 1=3 b D 5=6H =6 [5,7]. Here we focus on the depth of craters . This paper presents a study on the low-velocity impact response of lightweight steel foam concrete (LSFC) composite slabs. The LSFC composite slab consisted of a W-shaped steel plate, foam concrete and oriented strand board (OSB). Low-velocity impact tests on the LSFC composite slabs were conducted by employing an ultra-high heavy-duty drop hammer .Drop weight tests on components up to 2,000 joules Expanded temperature range Fixtures for a wide variety of components Many standardized tests More information . If the test is performed at low or elevated temperatures, the entire test setup must be housed . (compressed air) per impact or test: 10: 20: l: Required air-supply output-rate .The crash test speed range is 4.95 0.15 mi/h (7.96 + 0.24 km/h). Impact speed is measured using two optical speed sensors mounted on each side of the vehicle that are aimed downward to detect retroreflective tape strips on the crash hall floor. Each sensor is connected to its own

low velocity impact testing

Quadro de Sequência Lógica (QSL): 160121. Carga Horária Detalhes Legenda Copiar Link Período 1 360 a = 300 h Período 2 360 a = 300 h Período 3

low speed impact drop tests|impact force drop testing